Mathematics at work

Mathematics in the Aerospace Sector

It is projected that by 2016 there will be at least

500,000

jobs in aerospace maintenance and manufacturing that pay

well and offer opportunities for advancement. According

to the Bureau of Labor Statistics’ Occupational Outlook

Handbook, technological advances in the industry require

mechanics to have an especially strong background in

electronics — and mathematics — to keep pace with the

changes in the industry. Additionally, many aerospace firms

recently have begun to bring together teams composed of

customers, engineers and production workers to pool ideas

and make decisions concerning aircraft design at every

phase of its development. The aerospace industry provides

good job opportunities for individuals with teamwork skills

and proficiency in technology and applied mathematics.

Available Aerospace Jobs

Within the aerospace industry, there are a variety of entry-

level jobs that pay well and provide opportunities for

advancement — jobs for high school graduates with

postsecondary training or education but less than a four-

year college degree. High school graduates with 18 to 24

months of specialized postsecondary training leading to FAA

certification are qualified to become aircraft mechanics.

Core Mathematics Knowledge

in Today’s Aerospace Jobs

Developed by secondary, postsecondary, business,

industry and government leaders, the Career Cluster

Pathway Plan of Study for Maintenance, Installation

and Repair was designed to serve as a guide for

students’ educational and career goals. This Plan

of Study for individuals pursuing a career in aerospace

recommends a rigorous set of mathematics courses for

students to take at both the secondary and postsecondary

levels in traditional or vocational settings. This Plan

of Study shows in detail how the foundation provided

by courses such as Algebra I , Geometry, Algebra II,

Trigonometry or Statistics, Physics, and Computer

Applications equips high school graduates with the

mathematical knowledge and skills needed for success

on the job. Until high school graduates understand the

advanced mathematical skills used in the aerospace

sector, they will remain unable to meet the demands of

this high-growth industry.

| Jobs | Median yearly salary |

Percentage of total jobs by education/training (ages 25–44)* |

Number of total jobs | |||||||||

| High school | Some college | 2006 | 2016 | % change | ||||||||

| Aircraft mechanics and service technicians |

$47,700 | 33% | 57% | 122,500 | 135,500 | 11% | ||||||

| Avionics technicians | $46,900 | 31% | 65% | 15,700 | 17,000 | 8% | ||||||

*Remaining percentage of workers in occupation have a

bachelor’s degree or higher

Source: Bureau of Labor Statistics, U.S. Department of Labor, Occupational

Outlook Handbook, 2008–09 Edition.

Ensuring College and Career Readiness:

The American Diploma Project

In 2001, Achieve and several partner organizations

launched the American Diploma Project (ADP) to

identify a common core of English and mathematics

academic knowledge and skills, sometimes referred to

as “benchmarks,” that American high school graduates

need for success in college and the workforce. These

ADP benchmarks, released in the 2004 report Ready or

Not? Creating a High School Diploma That Counts, are

the result of two years of intensive research conducted

in colleges and universities as well as workplaces across

the country.

The real-world expectations identified by ADP are signi -

ficantly more rigorous than many current high school

graduation standards — which helps explain why many

high school graduates arrive at college or the workplace

with major gaps in their English or mathematics preparation.

To help pinpoint the academic knowledge and skills

required for future employment, ADP commissioned

leading economists to examine labor market projections

for the most promising occupations — those that pay

enough to support a family and provide real potential

for career advancement. ADP then surveyed officials

from 22 industries, ranging from manufacturing to

financial services, about the most useful skills for

their employees to bring to the job.

ADP also worked closely with two- and four-year post-

secondary faculty from five partner states to determine

the prerequisite English and mathematics knowledge and

skills required to succeed in entry-level, credit-bearing

higher education courses. These conversations revealed

an unprecedented convergence of the knowledge and

skills employers and postsecondary faculty say are

needed for new employees and freshmen beginning

credit-bearing coursework to be successful.

“Mathematics at Work” Series

Following up on the work of ADP, Achieve has produced a series of “Mathematics

at Work” brochures to

examine how higher-level mathematics is used in today’s workplaces. The

brochures present case studies

drawn from leading industries nationwide to illustrate the advanced mathematics

knowledge and skills

embedded in jobs that offer opportunities for advancement and are accessible to

high school graduates.

The series underscores the value of a rigorous high school curriculum in

mathematics. All high school

graduates — regardless of whether they enroll in college, join the workforce or

enter the military —

benefit from acquiring a comprehensive knowledge base and skill set in

mathematics.

Mathematics pilots

Career Preparation for Aircraft

Maintenance Technicians

The more than 100,000 aircraft maintenance technicians

(AMTs) at work in the public and private sector today have

a wide range of talents and skills that keep America’s

airplane fleet flying safely and smoothly. Although they

may have different educational backgrounds and areas

of expertise, all AMTs have one thing in common — a

solid foundation in mathematics, enabling them to earn

rigorous Federal Aviation Administration (FAA) certification

in airframe and power plant maintenance. From fabricating

parts and installing hydraulic systems to testing electrical

circuits and repairing airplane engines, AMTs possess the

highly sought-after mechanical knowledge and skills —

grounded in mathematics — that are valued by the airline

industry.

"Without a strong math and science

background, today’s technician is

not likely to progress far beyond

basic line maintenance."

La Vern Phillips, Regional Director

Aviation Institute of Maintenance

To earn FAA certification, applicants must have at least

a high school diploma and 18–24 months of specialized

postsecondary training, be it on the job, at a community

or technical college, or in a specialty occupation in the

military. Through a combination of oral and practical

exams, the FAA assesses the competency of applicants

in handling equipment such as ignition analyzers, riveters

and compression checkers. It also tests their familiarity

with scientific principles such as basic gas laws and

the properties of metals as well as the underlying

mathematical concepts that cover many core ADP

benchmarks. For example, the FAA requires that all

AMTs understand:

![]() Measurements with units

when replacing and

Measurements with units

when replacing and

fabricating fuselage parts

![]() Proportions and ratios

when assessing the electrical

Proportions and ratios

when assessing the electrical

needs of circuitry

![]() Solving equations with

one or more variables when

Solving equations with

one or more variables when

repairing hydraulic systems

![]() Calculating volume of

spheres, parallelepipeds and

Calculating volume of

spheres, parallelepipeds and

cylinders when assessing fuel needs

Modeling with linear equations when

computing

Modeling with linear equations when

computing

the center of gravity (CG) of an aircraft

The FAA certification process tests the understanding

future AMTs have of the array of instruments and

processes used on a daily basis, thereby evaluating

their ability to apply their mathematical skills to the

various challenges they face. Given the vital stakes

attached to aircraft safety, it also is critical that every-

one on the tarmac — pilots, engineers and AMTs — is

able to communicate with other members of the team

by speaking clearly about an airplane’s electronics

and mechanics through the universal language of

mathematics. Because no two aircraft are exactly

the same, AMTs must know when and how to apply

particular solutions to unique problems and modify

approaches from aircraft to aircraft as appropriate.

aviation safety

Safety in Numbers: Mathematics

in Action on the Tarmac

America’s future is up in the air — literally — and it

is up to airframe and power plant technicians to keep

America flying safely. The image of a tire-kicking, grease-

covered mechanic has long since been replaced by the

professionalism of today’s FAA-certified AMT. These

mathematically adept craftsmen ply their trade across

every facet of aviation.

Repairing a Crack in the Fuselage

Mathematical Reasoning and

Problem Solving

During the standard preflight check, AMTs are respon-

sible for inspecting the airplane for any suspicious signs

of wear and tear. Faced with a crack in an airplane’s

fuselage, a team of AMTs must first determine the most

effective method of repair . To do this, AMTs depend

on knowledge of the physical properties of metals and

composites — their strength, flexibility and

durability — when put under the stress

of flight. AMTs need to understand the

relationship between the materials used

to construct the aircraft and the parts

needed to make the repair, and know

the best methods for securing these

parts to the aircraft. Calculating

sheer strength also will help the

AMT select the most appropriate

materials for mending

the crack — such as

using metal rivets,

a composite

mixture of

resin and hardener, or the fabrication of a new part. If

a new part is required, the shape of the fabricated part

is another important variable — especially if the crack

has appeared on a part of the airplane with significant

curvature. In that situation, AMTs have little choice but

to create a new part to replace the damaged section.

Fabricating New Parts for Repair

Geometry, Algebra and Teamwork

Depending on the size of the crack, the weight

restrictions and the bend allowance of the fabricated

material, AMTs must perform a sophisticated series

of algebraic and geometric calculations to determine

the amount of material needed for the replacement

part, the shape it should take, and the maximum

weight allowance and other tolerances.

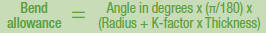

For example, creating a patch for a particularly curved

section of the airplane’s fuselage (or wing) requires

calculating the bend allowance of sheet metal — a

dimensional adjustment that must be factored in to

ensure the safety of the replacement part. When AMTs

bend metal to the desired form, the material of the

outside angle is stretched, while the material on the

inside angle is compressed. Determining the proper

bend radius is essential to constructing a strong and

sound part. Too small a radius can cause further cracking,

while too large a radius can result in costly overruns

of material, excess weight and ultimately a disruption

in the airplane’s CG. To properly calculate the bend

allowance, AMTs must measure the length of the

brackets and the material thickness along with the

angle and radius of the bend. They also must determine

the “neutral axis,” or the K-factor — the percent of

the material thickness where there is no stretching or

compressing. Once the bend allowance is calculated,

technicians can fabricate a new part; choose the

appropriate rivet size, rivet pitch and tooling; and

successfully repair the aircraft.

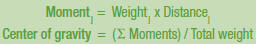

Maintaining Center of Gravity

Measurement and Proportions

A team of AMTs working together also must consider the

effect the repair will have on the airplane’s CG. Because

an aircraft is designed to be balanced forward and aft,

the CG is located in a precise range along the chord

of the wing — the distance between the leading and

trailing edge of a wing. If the actual balance point is too far

forward or too far aft, the pilot may experience difficulty

maintaining level flight.

When making adjustments to an airplane’s fuselage,

AMTs must find the CG by weighing the aircraft with

platform scales or by using load cells positioned at

designated points along the fuselage. AMTs must

calculate these specific weights and the dimensions

of those points to determine “moments” along an axis

and determine the range within which the CG can be

located. If, after making the repair, the actual CG falls

beyond the approved envelope, the technicians need

to calculate where and how much ballast they should

add to reposition the CG within the approved range.

Since ballast is useless weight and only wastes fuel,

fabricating durable but lightweight replacement parts

is key to minimizing the need for additional costly

adjustments to the airplane’s CG.

Keeping Airplanes Flying

Keeping an aircraft ready for flight requires AMTs to make

dozens of complex decisions every day as they inspect,

repair and maintain a wide variety of aircraft. Ensuring

an airplane’s airworthiness and the safety of the crew

and passengers is not based on a wing and a prayer —

it is grounded in a sophisticated understanding of how

to apply the principles of algebra, trigonometry and even

calculus to airplane maintenance. Keeping America flying

safe and sound is just another example of mathematics

at work today.

"Whether it is manufacturing a new

component, repairing a damaged

structure, performing an aircraft

weight and balance calculation, or

performing operational checks ,

mathematics is essential."

E. Wayne Lee

Head Aircraft Services Branch

NASA

Mathematics + Teamwork = Success

AMTs must have a strong foundation of mathematical

knowledge and skills to successfully inspect, repair and

maintain the airworthiness of an airplane. AMTs need

to tap into their problem-solving skills to diagnose any

potential issues that arise and make well-informed

decisions to resolve those problems quickly and

efficiently.

When a team of AMTs identifies a crack in the fuselage

of an airplane, for example, they must first hone in on

the best repair solution, using inductive and deductive

reasoning. AMTs also use their knowledge of various

materials’ properties and sheer strength to determine

the appropriate materials and fabrication methods to

repair a crack on a particular part of the aircraft.

The technicians rely on many mathematics-based skills

to fabricate a new part, including using real and rational

|numbers, calculating ratios and proportions, and measuring

plane figures. Computing the bend allowance requires

AMTs to use algebraic and geometric concepts to ensure

that the newly fabricated part fits just right.

AMTs must monitor the consequences of their actions on

the airplane’s overall airworthiness and performance. When

the team of AMTs installs the new part, they may shift the

airplane’s CG. If so, the AMTs will need to calculate a new

CG, requiring the application of such mathematics skills

as converting units of measurement and solving equations

with one or more variables.

Although fabricating a new part to repair a crack in an

airplane relies on AMTs’ mathematical and technological

knowledge, teamwork also is critical. ADP research shows

that both in the college classroom and in the work-

place, professors and employers identify collaboration

and communication as important factors for success.

Since AMTs may have individualized training in particular

systems, such as engine repair, AMTs often work together

and learn from each others’ expertise to ensure that every

airplane is in top-flight condition.

The required postsecondary training — be it in the

field or in the classroom — combined with the rigorous

FAA certification test and the on-the-job instruction, all

underscore the need for future AMTs to leave high school

|having completed a rigorous set of courses aligned with

college and career readiness expectations, especially in

mathematics.

"Mathematics plays a huge role

in the day-to-day activities of

aircraft mechanics. Consciously

or subconsciously, mechanics

utilize their knowledge of math.

The basic principles of algebra,

trigonometry and even calculus

are applied towards ensuring the

airworthiness of the aircraft and

the safety of the crew."

E. Wayne Lee

Head Aircraft Services Branch

NASA

| Prev | Next |